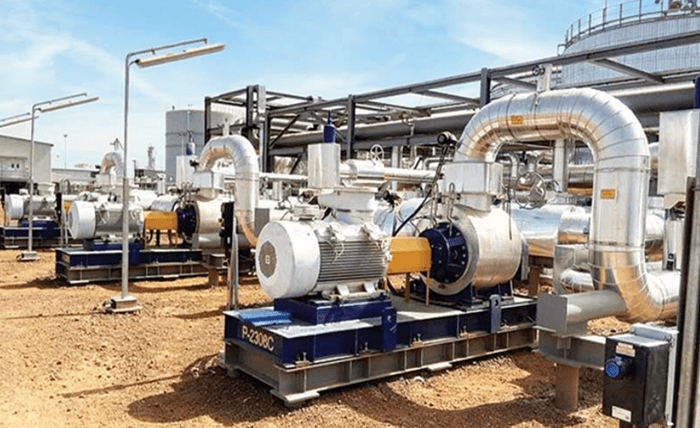

In today’s industrial landscape, efficiency is paramount. As businesses strive to cut costs and minimize their environmental impact, the focus on energy-efficient equipment has never been greater. Among the critical components of many industrial processes are transport pumps, which play a vital role in moving fluids and materials within various applications. This article explores the significance of energy-efficient transport pumps, particularly focusing on industrial gear pumps and progressing cavity pumps, and how these technologies can lead to substantial cost savings and a reduced environmental footprint.

Understanding Transport Pumps

Transport pumps are essential devices used in numerous industries, including manufacturing, chemical processing, food and beverage, seismic surveys, and wastewater management. Their primary function is to move liquids, slurries, and gases from one location to another. Depending on the application, transport pumps can handle a wide range of fluids, from water and oils to more viscous substances such as slurries or chemicals.

Types of Transport Pumps

There are various types of transport pumps, each designed for specific applications. Two notable types are:

1. Industrial Gear Pumps: Industrial gear pumps utilize gears to move fluids. They are known for their robustness, durability, and ability to handle high pressures and viscosities. Gear pumps are often used in applications where precise flow control is required, such as in lubrication systems or the transfer of chemicals.

2. Progressing Cavity Pumps: Progressing cavity pumps consist of a helical rotor that turns within a stator, creating a series of cavities that transport fluid through the pump. These pumps are particularly effective for handling viscous fluids and are commonly used in the food and beverage industry, as well as in the treatment of wastewater.

The Importance of Energy Efficiency

Energy efficiency has become a significant focus in industrial operations, driven by rising energy costs and increased regulatory scrutiny regarding environmental practices. For many industries, transport pumps represent a substantial portion of energy consumption. By investing in energy-efficient pump technologies, businesses can achieve significant savings in operational costs while also reducing their carbon footprint.

Cost Savings

Investing in energy-efficient transport pumps can lead to significant cost savings in several ways:

- Reduced Energy Consumption: Energy-efficient pumps are designed to operate at lower energy levels while maintaining optimal performance. This leads to reduced electricity bills and overall operating costs.

- Lower Maintenance Costs: Energy-efficient pumps often feature advanced designs that reduce wear and tear on components. This results in less frequent maintenance, lower repair costs, and extended equipment lifespan.

- Improved Process Efficiency: Efficient pumps can help streamline processes, resulting in higher productivity and lower costs associated with downtime and inefficiencies.

Environmental Impact

In addition to cost savings, energy-efficient transport pumps contribute to a reduced environmental impact. Here are a few ways these pumps help promote sustainability:

- Reduced Greenhouse Gas Emissions: By lowering energy consumption, businesses can significantly reduce their greenhouse gas emissions. This is particularly important as industries seek to meet regulatory standards and demonstrate their commitment to environmental responsibility.

- Conservation of Resources: Efficient pumps require less energy to operate, which in turn conserves natural resources. This is crucial in an era of increasing demand for energy and resources.

- Minimized Waste: Many energy-efficient pumps are designed with improved sealing and containment features, reducing the risk of leaks and spills. This not only protects the environment but also minimizes waste management costs.

Selecting the Right Energy-Efficient Transport Pump

When considering energy-efficient transport pumps for your industrial applications, there are several factors to keep in mind:

1. Application Requirements

Understanding the specific needs of your application is essential. Consider the type of fluid being transported, its viscosity, temperature, and any special handling requirements. Selecting a pump that aligns with these parameters will ensure optimal performance and efficiency.

2. Pump Design and Efficiency Ratings

Look for pumps with energy efficiency ratings and certifications. Many manufacturers provide performance data that highlights the energy consumption of their products. Additionally, advanced designs, such as variable frequency drives (VFDs), can further enhance energy efficiency by allowing for adjustable pump speeds based on demand.

3. Maintenance and Reliability

Choose pumps that are designed for reliability and ease of maintenance. Regular maintenance is crucial for maintaining energy efficiency over time. Pumps with fewer moving parts and simpler designs often require less maintenance, leading to lower overall operational costs.

4. Vendor Support and Expertise

Partnering with a knowledgeable vendor can significantly impact your success in selecting and implementing energy-efficient transport pumps. Look for vendors with expertise in your industry who can provide guidance on the best pump solutions for your specific needs.

The Future of Energy-Efficient Transport Pumps

As industries continue to evolve and adapt to changing environmental standards, the development of energy-efficient transport pumps will likely remain a priority. Innovations in pump technology, materials, and design will play a crucial role in improving efficiency and reducing the environmental impact of industrial processes.

Emerging Technologies

The future may see increased integration of smart technologies into transport pumps, allowing for real-time monitoring and control. These advancements can help operators optimize pump performance, reduce energy consumption, and address potential issues before they escalate into costly problems.

Industry Collaboration

Collaboration between manufacturers, engineers, and end-users will be vital in driving the development of energy-efficient transport pumps. By sharing insights and best practices, the industry can continue to innovate and improve pump efficiency, ultimately benefiting both businesses and the environment.

Conclusion

Energy-efficient transport pumps represent a crucial component in the quest for cost savings and environmental responsibility in industrial applications. By understanding the different types of pumps, evaluating their efficiency, and selecting the right equipment for specific needs, businesses can significantly reduce their energy consumption and operational costs. Moreover, the positive impact on the environment through reduced emissions and resource conservation is an essential consideration for companies looking to enhance their sustainability efforts. Investing in energy-efficient transport pumps is not just a smart business decision; it’s a commitment to a more sustainable future.