The term CNC is an acronym that refers to Computer Numerical Control. It is a technology that uses computer software to automate the operation of machine tools, which are used in various manufacturing processes. The CNC system is programmed to control the movement of the machine tools and produce accurate and precise parts or products. In this article, we will discuss the meaning and significance of CNC, and how it is used in different industries.

What is CNC?

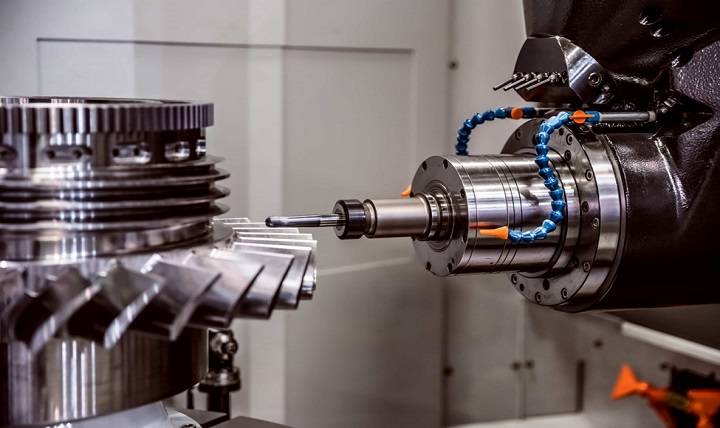

CNC is a manufacturing technology that is widely used in various industries, including automotive, aerospace, electronics, and medical devices. It is a computer-based system that controls the movement of machine tools, such as lathes, mills, routers, and grinders, to produce high-precision parts or products. The CNC system uses a programming language, known as G-code, to control the movement of the machine tools. The G-code is a language that tells the machine tool where to move, how fast to move, and what actions to perform.

Significance of CNC

CNC technology has revolutionized the manufacturing industry by improving efficiency, accuracy, and productivity. It has replaced manual methods of manufacturing, which were time-consuming, error-prone, and required skilled labor. With CNC, manufacturers can produce parts or products with greater precision and consistency, and in a shorter amount of time. CNC machines can run 24/7, allowing for continuous production and faster turnaround times.

The use of CNC technology has also reduced waste and improved safety in the manufacturing process. CNC machines are equipped with safety features, such as emergency stop buttons and protective guards, to prevent accidents and injuries. Additionally, CNC machines are programmed to use materials efficiently, reducing waste and minimizing the environmental impact of manufacturing processes.

Applications of CNC

CNC technology is used in various industries, including:

Automotive: CNC machines are used to manufacture engine parts, suspension components, and other automotive parts.

Aerospace: CNC machines are used to manufacture aircraft parts, such as engine components, landing gear, and wing structures.

Electronics: CNC machines are used to manufacture electronic components, such as printed circuit boards (PCBs), computer parts, and mobile phone parts.

Medical devices: CNC machines are used to manufacture medical devices, such as implants, surgical instruments, and prosthetics.

Conclusion

In conclusion, CNC is an acronym that stands for Computer Numerical Control. It is a technology that has revolutionized the manufacturing industry by improving efficiency, accuracy, and productivity. CNC machines are programmed to control the movement of machine tools, producing high-precision parts or products. The use of CNC technology has also reduced waste and improved safety in the manufacturing process. CNC machines are used in various industries, including automotive, aerospace, electronics, and medical devices. With its many benefits, CNC technology is likely to continue to play a significant role in the manufacturing industry for years to come.